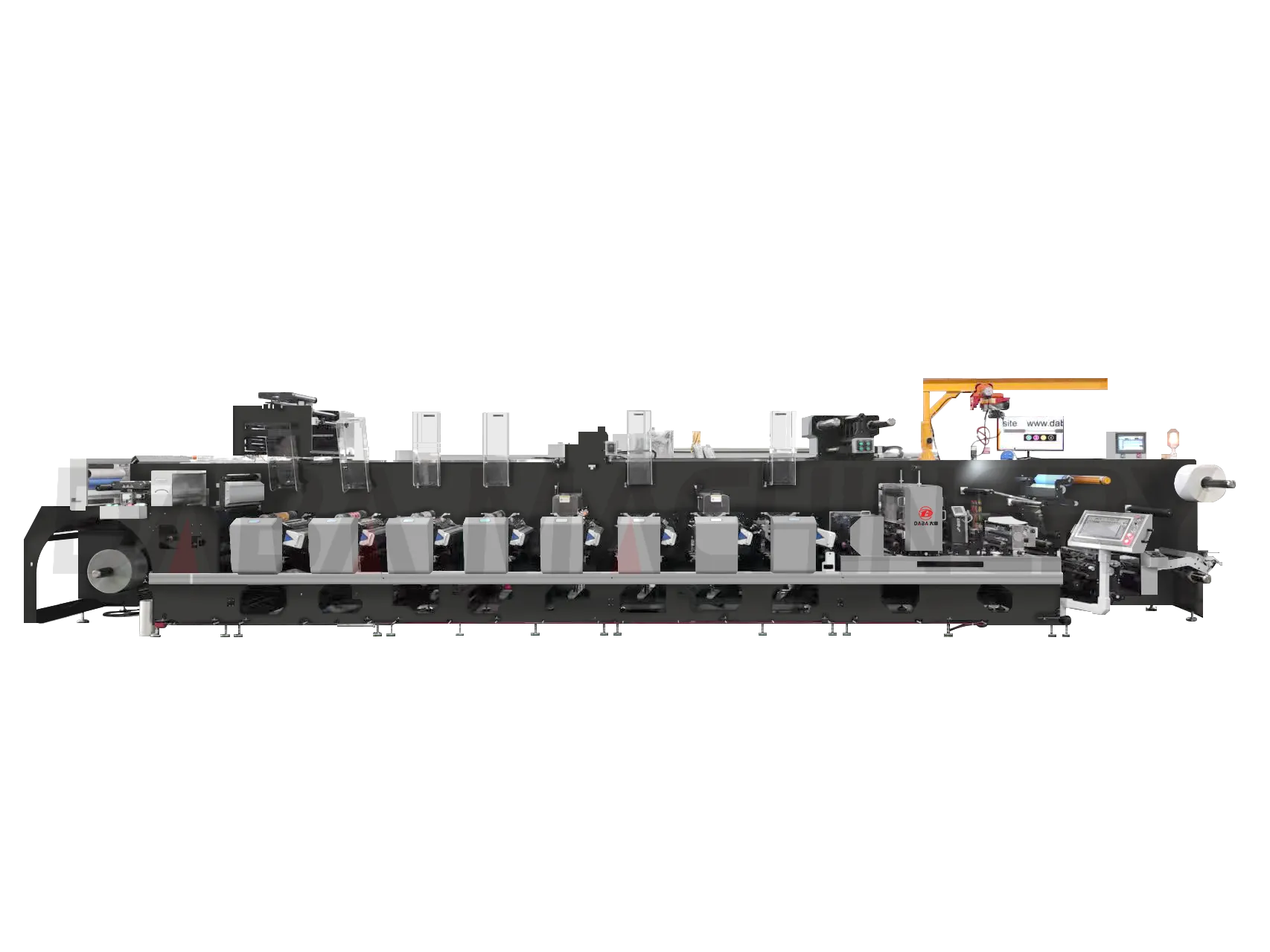

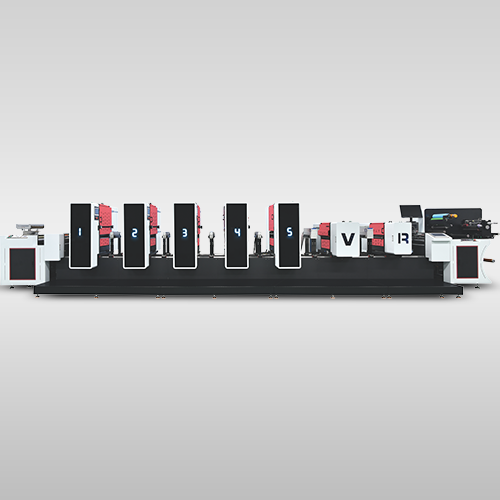

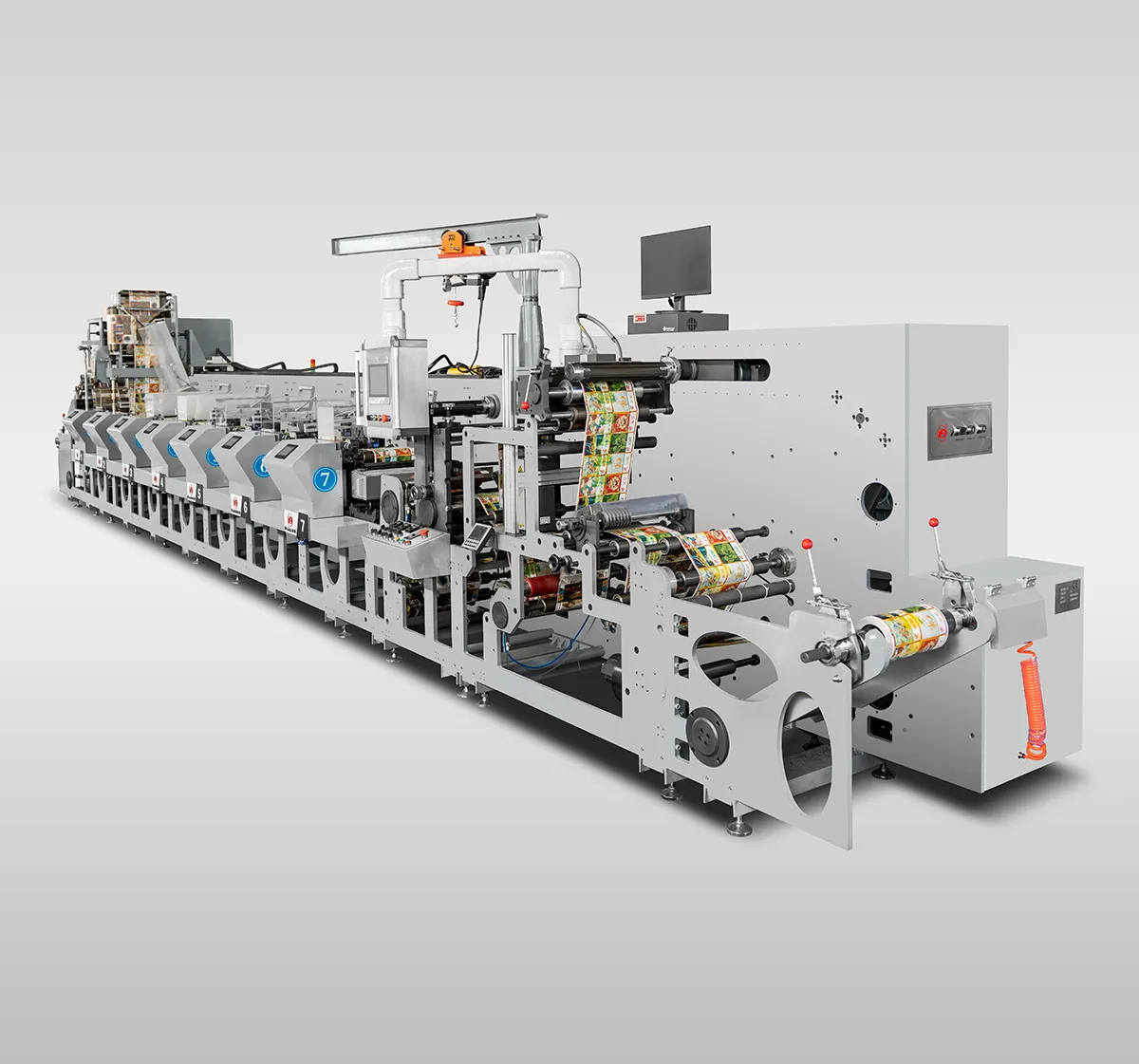

DBRY-L370H Series Full-Servo In-Line Flexo Printing Press

OverView

The DBRY-L370H Series is a next-generation unit-type flexographic printing machine designed to deliver outstanding print quality, precise color registration, and efficient performance at high speeds. Equipped with a total of 37 independent servo motors and an advanced Inovance control system, this press ensures ultra-accurate operation across all 8 printing units. Whether you're printing on labels, BOPP films, or aluminum foil, the DBRY-L370H Series handles a wide range of materials with ease. Its modular structure, fast ink system, and energy-saving LED UV dryers make it an ideal solution for high-demand, short-run, or variable printing jobs in today's competitive packaging market.

Features

Advanced Servo Control System

Equipped with 37 Inovance servo motors (4 per color unit), ensuring precise registration and stable performance at high speeds up to 150m/min.

Modular Unit-Type Design

Independent color units with petal-structure printing stations allow for quick maintenance, easy upgrades, and high print accuracy.

High-Precision Color Registration

Automatic pre-registration and 360° servo-driven longitudinal adjustment ensure exceptional registration, even on demanding materials like BOPP and foil.

Fast Job Changeover

Quick-change ink trays, petal-type printing rollers, and automatic pressure adjustment significantly reduce setup time.

Film-Friendly Printing

Integrated water chilling rollers on both anvil and impression cylinders help stabilize thin film materials during printing, reducing wrinkles and deformation.

Energy-Efficient LED UV Drying

Advanced frequency-controlled LED UV system saves up to 30% energy, with adjustable power for each station based on machine speed or manual setting.

Smart Operation Interface

Dual-language (EN/CH) touchscreen control with automatic fault detection, job memory, and optional movable touch panels for user convenience.

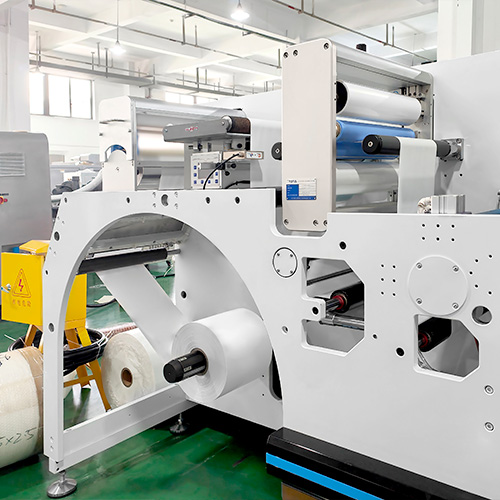

Comprehensive Web Handling System

Includes automatic unwinder/rewinder, servo-driven tension control, ultrasonic web guide, and optional web cleaner and corona treatment unit.

Optional Converting & Finishing Functions

Fully configurable with rotary die-cutting, cold foil stamping, lamination, sheeting, slitting (razor/rotary/pneumatic), and delam-relam unit.

Parameters

Printing Capabilities

-

Max. Printing Speed

150m/min

-

Max. Printing Width

370mm

-

Repeat Length Range

254–600mm

-

Number of Color Units

8

-

Registration Accuracy

±0.1mm(with servo system)

-

Pre-registration

Automatic

-

Color Registration Control

360° Servo-driven

Mechanical Configuration

-

Printing Roller Type

Petal-type

-

Pressure Adjustment

Motorized / No manual need in most cases

-

Anilox Roller Mounting

Tool-free, gearless

-

Ink Supply System

Quick-change ink trays

-

Chilling System

Integrated water-cooled drums

-

Drying System

LED UV (energy-efficient)

Material Handling

-

Max. Web Width

370 mm

-

Max. Unwinding Diameter

1000 mm

-

Max. Rewinding Diameter

900 mm

-

Web Path Length

9.6 meters (compact design)

-

Tension Control

Servo-controlled

-

Web Guiding

Ultrasonic + BST System

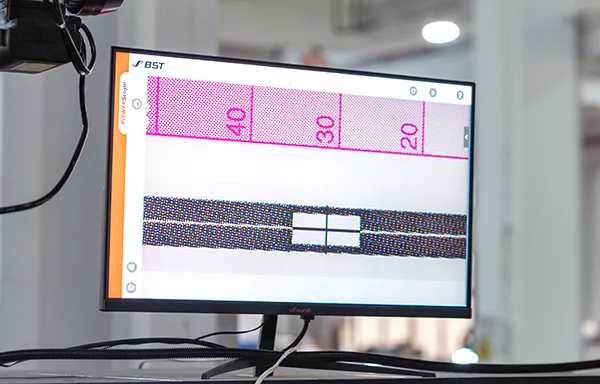

Control & Automation

-

Control System

Inovance Servo System

-

Total Servo Motors

37 pcs

-

Touchscreen Interface

Fixed & Optional Movable (EN/CH)

-

Fault Detection

Automatic with Alarm

-

Video Monitoring

BST brand, 22" screen

Supported Materials & Applications

Semi Glossy Paper

Retail Labels

Supermarket product labels, food packaging (biscuits, bread bags)

Logistics Labels

Express barcode labels, warehouse shelf number labels

Price Tags

Retail price tags, promotional labels

Writing Paper

File Labels

Document archiving labels, file classification tags

Envelope Labels

Mailing labels, address labels

Office Labels

Office supplies classification stickers

Kraft Paper

Handmade Soap Labels

Natural soap packaging labels

Eco Gift Boxes

Eco-friendly gift box stickers

Coffee Seals

Café pour-over coffee seals

.webp)

PET (Polyester)

Battery Labels

Warning labels for batteries

Device Labels

Phone back labels (e.g., "Do Not Remove" labels)

Equipment Labels

Industrial equipment nameplates

PVC

Vehicle Graphics

Car body advertising stickers

Window Decals

Glass window stickers

Cosmetic Labels

Bottle decoration labels

PE (Polyethylene)

Bottle Labels

Shower gel bottle labels

Frozen Food Labels

Freezer-safe food labels

Baby Bottle Labels

Baby bottle stickers

Thermal Paper

Express Labels

Express shipping labels

Scale Labels

Supermarket scale labels

Price Labels

Cash register price labels

Metal Foil

Wine Labels

Premium wine bottle labels

Perfume Labels

Luxury perfume bottle labels

Brand Labels

Brand logo metal stickers

Videos

Machine Structure Details

Customer Success Stories

James T., FlexoPack Solutions (USA)

"After running our DBRY-L370H Series for 18 months, we've achieved ±0.08mm registration consistency across 8-color snack packaging jobs. The servo system reduced our material waste by 22% compared to our previous gear-driven machine. The water-chilled drums eliminated film stretching issues we used to have with heat-sensitive laminates."

Dr. Elena M., SecureLabel Pharma (Germany)

"The BST inspection system on our machine catches micro-defects in barcode printing that would have caused compliance issues. We've had zero product recalls since implementation. The petal-type sleeve changeover (under 5 minutes) is crucial for our small-batch GMP production."

Raj P., HeavyPack Industries (India)

"Printing on 500gsm corrugated material was challenging until we got this press. The independent servo pressure control handles substrate variations perfectly. Our 24/7 operation has achieved 98.6% uptime - the Inovance PLC system's predictive maintenance alerts prevent unexpected breakdowns."

FAQs

What materials can this press handle?

The DBRY-L370H Series processes paper (80-500gsm), films (BOPP/PET/PE 12-250µ), aluminum foil (7-50µ), and self-adhesive materials with servo-controlled tension accuracy of ±0.1N.

What's the maximum printing speed?

150m/min for most substrates, with stable registration maintained up to 120m/min for delicate films. Actual production speed depends on ink drying requirements.

How many colors can it print simultaneously?

Standard configuration is 8 colors, expandable to 10 colors with optional tower units. Each station has independent servo control for precise registration.

What makes the registration system so accurate?

Our dual-phase system combines pre-registration (±0.5mm via PLC) with running registration (P+F sensors scanning at 2000Hz), achieving ±0.1mm tolerance during production.

How fast is job changeover?

Petal-type sleeves enable plate changes in 5 seconds (vs 2-3 minutes for conventional sleeves). Complete job changes average 15-25 minutes including ink system cleaning.

What drying systems are available?

Standard LED-UV (18kW, 30% energy saving), with optional hot air (for water-based inks) or hybrid UV/IR systems. All feature automatic power adjustment.

Can it print on both sides of material?

Yes, via the movable turn bar option. For adhesive materials, our delam/relam unit allows printing on the glue side before recombining layers.

What's the maximum repeat length?

254-600mm adjustable range. Larger repeats (up to 800mm) available with optional gear kits. All adjustments are digital via the touchscreen.

How is web tension controlled?

21 servo motors with closed-loop feedback maintain tension within ±0.5% from unwind to rewind, automatically compensating for diameter changes.

What quality control features are included?

Standard BST inspection system with 22" monitor, capable of detecting 0.1mm defects, color variation >ΔE1.5, and barcode verification (optional).

Machine Display